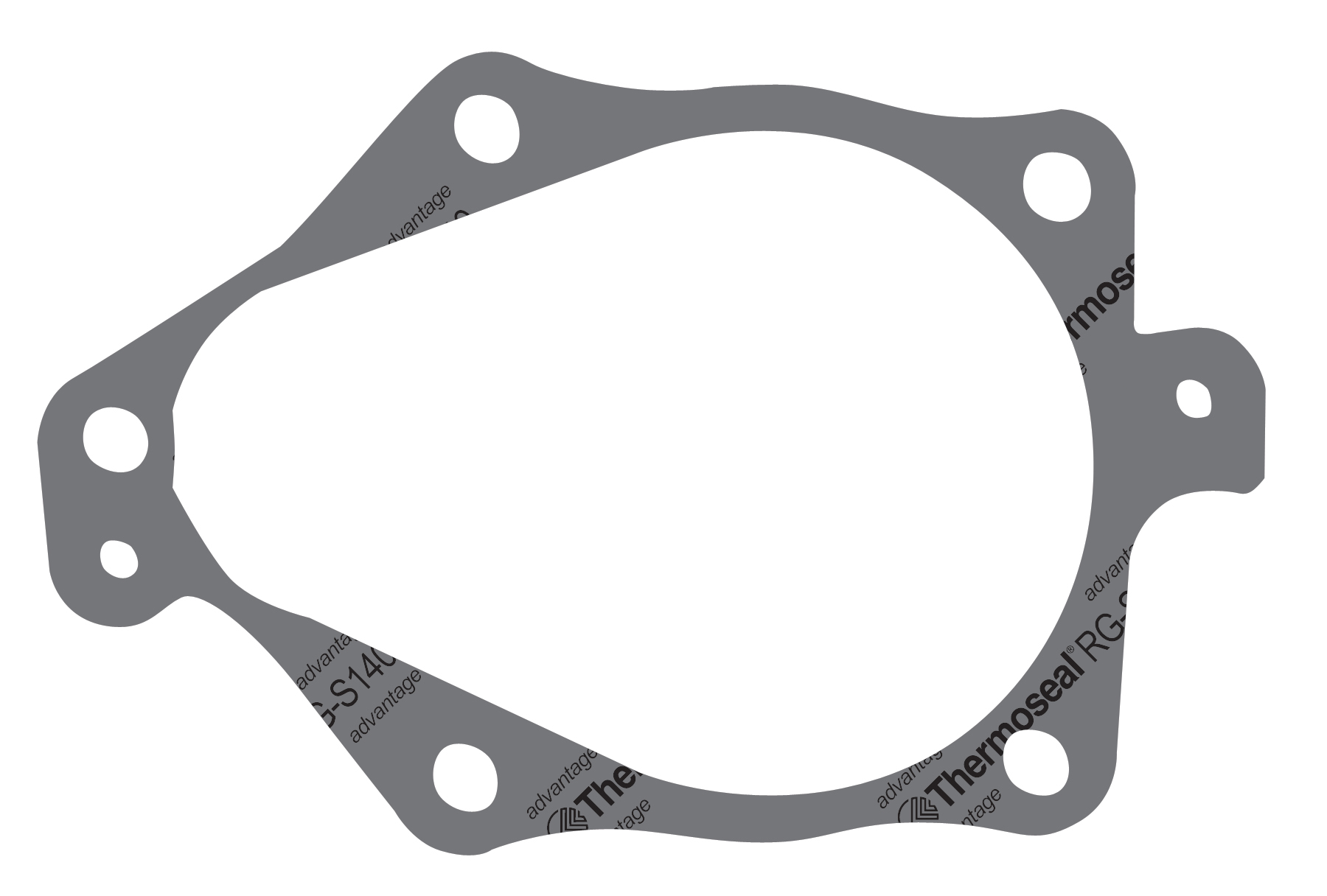

Thermoseal RG-S140

Beater Addition Rolled Goods

KLINGER Thermoseal's Advantage Roll Goods materials perform in a wide range of applications from low-cost aftermarket to higher performing OEM seals. Continuous length rolls allow efficient and economical fabrication with high speed die-cutting equipment. When your customers want an "equivalent" or alternative to the currently specified material, there is an Advantage Roll Good for the job.

RG-S140 is a controlled-swell gasket material that provides excellent sealing where initial gasket conformability is required to compensate for flange out of flatness or roughness. After establishing initial sealability, the styrene-butadiene binder fully vulcanizes with time and heat of component operation to provide long-lasting performance. RG-S140 contains a unique blend of aramid, mineral, and cellulose fibers and mineral fillers to provide enhanced crush and temperature resistance. A factory-applied release coating on both sides aids in flange removal. Typical applications include gaskets for sealing hot oil or coolant in machinery including small engines and automotive and heavy-duty diesel engines.

RG-S140 is suitable for applications with intermittent operating temperatures up to 550°F (288°C).

Typical Values Refer to 0.031" Thick Material Unless Noted

| Temperature maximum | 550°F (288°C) |

| Density ASTM F1315 | 87 lb/ft3 (1.4 g/cm³) |

| Compressibility ASTM F36 J | 12 - 25 % |

| Recovery ASTM F36 J | Minimum 35 % |

| Tensile strength ASTM F152 | Minimum 870 psi (9 MPa) |

| Fluid Resistance after immersion in Oil IRM903 Weight Increase Thickness Increase |

Maximum 45 % Maximum 60 % |

|

Binder Type

|

Styrene butadiene rubber

(partially vulcanized)

|

| ASTM F104 Line Call Out | F729900E09M9 |

| Color | Grey |