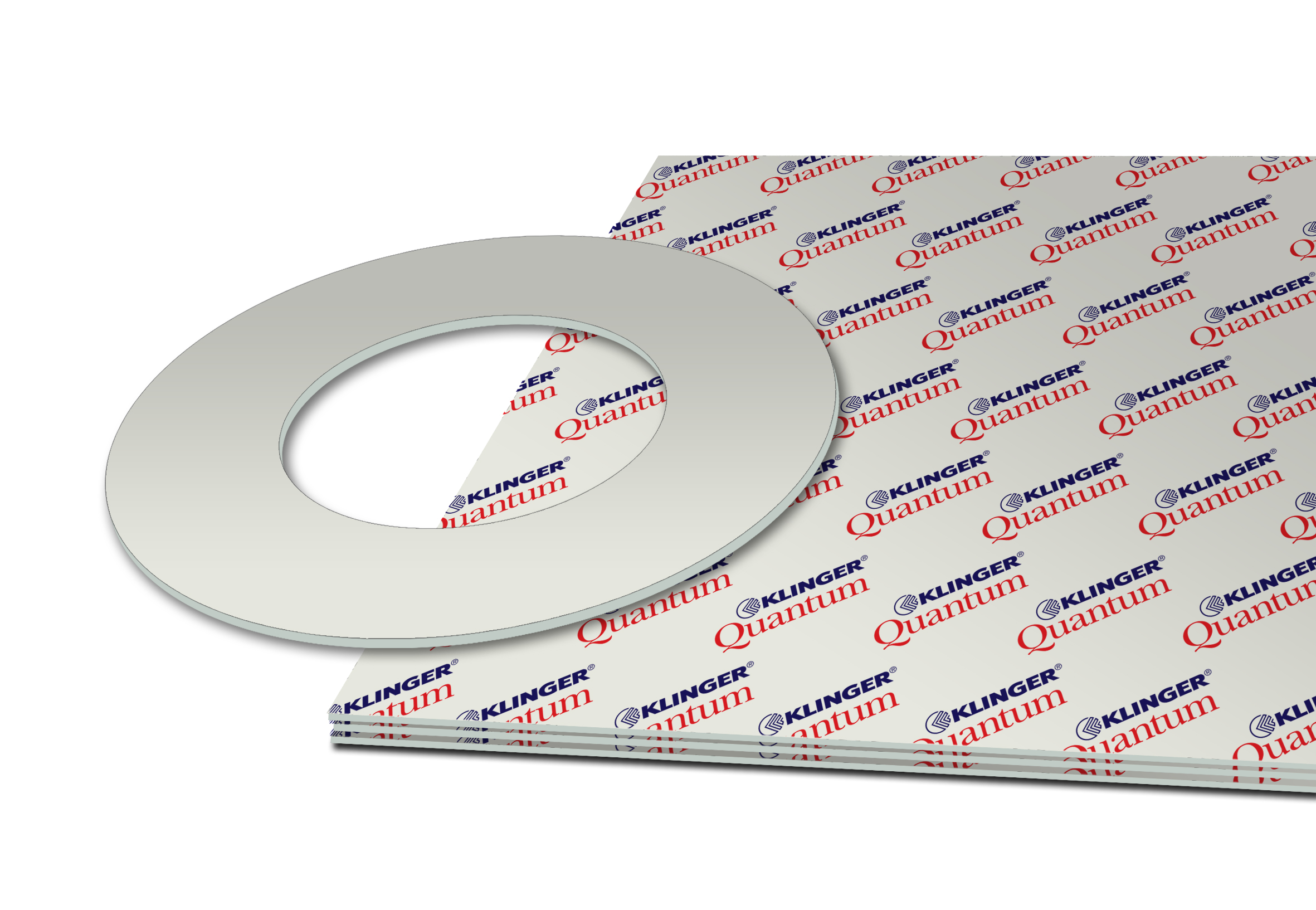

KLINGER® QUANTUM

Unique gasket material with the highest flexibility at high temperatures

KLINGER® Quantum is the first fiber-reinforced gasket material in the world that is exclusively HNBR-bound. Together with a unique production process developed specifically for the purpose, this material can be used at higher temperatures and with a much wider range of media than any other fiber-reinforced gasket material that is currently available.

This material is suitable for use in oils, water, steam, gases, salt solutions, fuels, alcohols, weak organic and inorganic acids, hydrocarbons, lubricants, and refrigerants. KLINGER Quantum is manufactured with high-quality fiber and filler compound reinforced with a high-temperature resistant HNBR matrix.

Certificates and approvals

- BAM-tested

- DIN-DVGW

- TA-Luft (Clean air)

- Fire-Safe acc. to DIN EN ISO 10497

- FDA conformity (must specify unbranded

Bending Test according to ISO 178

To evaluate flexibility potentials of sealing materials, the three-point bend test is often used to determine the flexural properties of compressed fiber materials. In this test, the test specimen is deformed in the middle between the contact faces with a constant testing speed until it breaks, or until the deformation has reached a specified value.

For the flexibility test, specimens of a fiber reinforced reference material and of KLINGER® Quantum were treated for 48 hours at 200°C (392°F) and at 250°C (482°). The results of the test on these artificially aged samples provide information on the aging resistance of the two different materials and underscore the high performance of KLINGER® Quantum.

The unique behavior of KLINGER® Quantum manifests itself even more impressively in long-term tests. For this purpose, a fiber reinforced reference material, together with KLINGER® Quantum was again treated at a temperature of 200°C (392°F) for 300 hours and 600 hours. After 600 hours at a temperature of 200°C KLINGER® Quantum, shows a flexibility that is 8 times higher than known fiber-reinforced gasket materials.

There are often strong pressure shocks, particularly in steam applications, that result in damage to the gasket material. A more flexible gasket that withstands greater expansions without rupture is a factor that contributes to a safer, more reliable gasket joint.

TYPICAL VALUES REFER TO 2.0 MM THICK MATERIAL UNLESS NOTED

| Compressibility ASTM F36J | 8 - 14 % |

| Recovery ASTM F36J | 50 % minimum |

| Stress Relaxation DIN 52913 50 MPa, 16h/347°F (175 °C) 50 MPa, 16h/572°F (300 °C) |

32 MPa 30 MPa |

| Stress Relaxation BS 7531 40 MPa, 16h/572°F (300 °C) |

29 MPa |

| KLINGER Hot Compression Test Thickness Decrease 73°F (23 °C) Thickness Decrease 572 °F (300 °C) Thickness Decease 752 °F (400 °C) |

10 % initial 14 % additional 20 % additional |

| Tightness DIN 28090-2 | 0.02 mg/s x m |

| Thickness Increase ASTM F146 after immersion in ASTM Oil IRM 903, 5h/300°F (149°C) ASTM Fuel B, 5h/73°F (23°C) |

3 % 5 % |

| Average Dielectric Strength Ed | 18.5 kV/mm |

| Density | 106 lb/ft3 (1.7 g/cc3) |

| ASTM F104 Line Call Out | F712122B3E22M5 |

| Color | White |

The pressure/temperature graphs shown are the most current method of determining the suitability of a gasket material in a known environment. However, chemical compatibility must also be considered.

In area 2 appropriate measures are necessary for installation of the gasket to ensure maximum performance. Please call or refer to KLINGERexpert for assistance.

In area 3 do not install gaskets in these applications without first referring to KLINGERexpert or contacting KLINGER Thermoseal's technical support service.