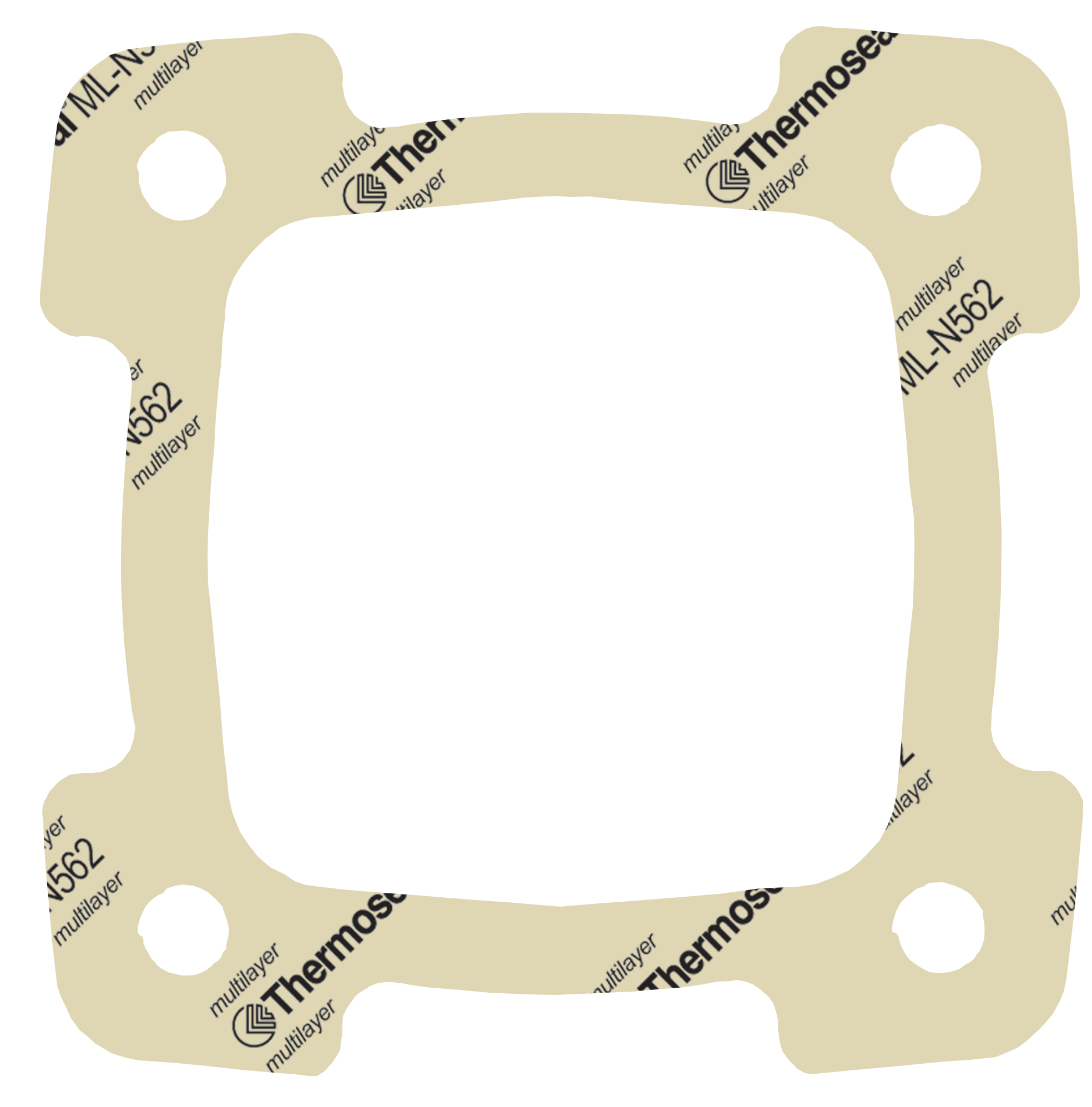

Thermoseal ML-N562

High performance multi-layer sheet

KLINGER Thermoseal's Multi-Layer Technology materials provide both exceptional interfacial and interstitial sealability. Conformable outer layers prevent leakage between the gasket and flanges and a strong high-density core provides structural support while preventing leakage through the gasket.

ML-N562 is a synthetic fiber and nitrile butadiene gasket material designed for difficult sealing applications with very low flange pressure or very rough surface finishes. It combines a Multi-Layer Technology structure for exceptional low flange pressure sealability and exceptional torque retention together with a more compressible core. ML-N562 provides heat and chemical resistance in coolant, lubricant, and hot air applications.

Typical applications include automotive, marine, and small engine applications with intermittent operating temperatures up to 500°F (260C°).

Typical Values Refer to 1/16" Thick Material Unless Noted

| Temperature maximum | 500°F (260°C) |

| Pressure maximum | 1400 psi (9.63 MPa) |

| Density ASTM F1315 | 87 lb/ft3 (1.4 g/cm³) |

| Compressibility ASTM F36 J | Minimum 15 % |

| Recovery ASTM F36 J | Minimum 45 % |

| Gas Permeability DIN 3535/6 | < 0.2 ml/min |

| Weight Increases ASTM F146 After immersion in Fuel B for 5h/73°F |

Maximum 10 % |

| Thickness Increases ASTM F146 After immersion in Oil IRM 901 for 5h/300°F After immersion in Fuel B for 5h/73°F |

< 10 % < 15 % |

| Creep relaxation ASTM F38 B (1/32") | Maximum 20 % |

| Sealability ASTM F37 (1/32") | < 0.20 ml/hr |

| ASTM F104 Line Call Out | F715121B3E12K6M4 |

| Color | White or Black |